3 1. Overview

1.1 Application Occasions

This high-voltage DC power supply is a custom-made special power supply, featuring small size, light weight, high efficiency, and built-in fan for heat dissipation. Its maximum operating efficiency is ≥97%. The power module adopts an aluminum shell design, which is lightweight, aesthetically pleasing, and waterproof, and can be used as a substitute for imported high-voltage DC module power supplies.

1.2 Product Features

- DC-DC isolated power converter: Converts the input 1000V DC power into 60V DC power in an isolated manner, with a rated output power of 24KW.

- High power density, small size, and light weight.

- Designed to meet power supply reliability requirements: Equipped with over/under-voltage protection for input, and over-voltage protection, current limiting, short-circuit protection, and over-temperature protection for output.

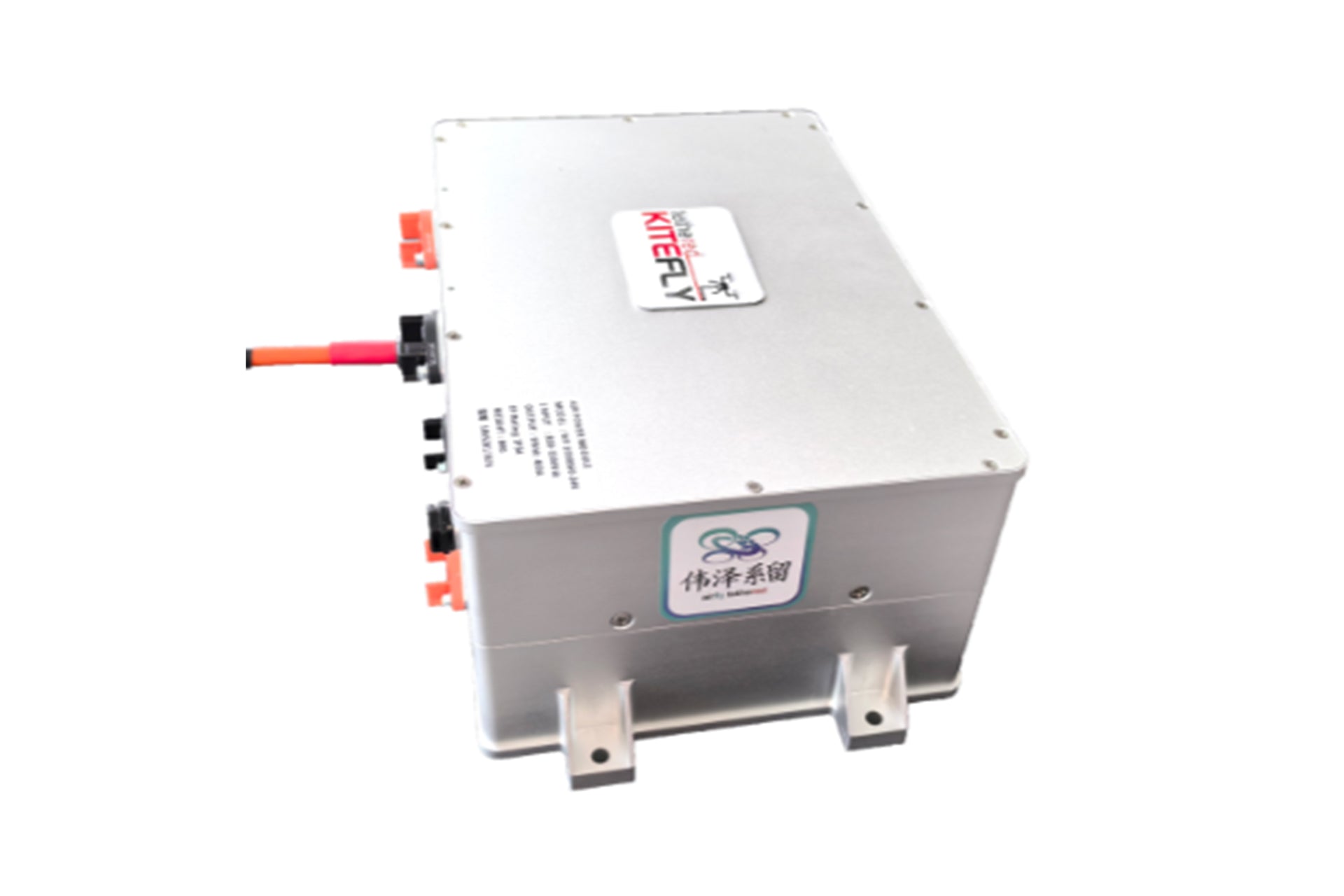

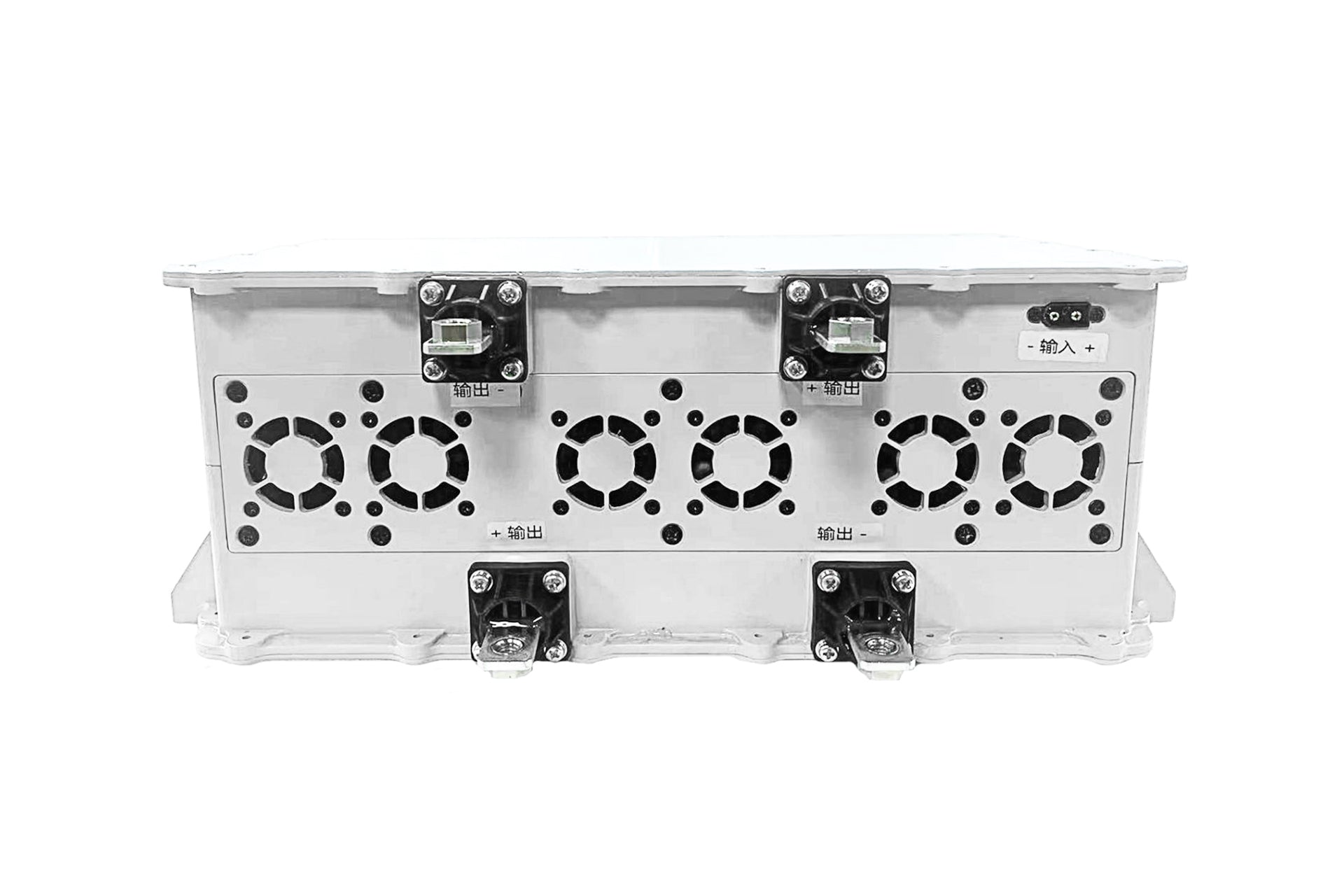

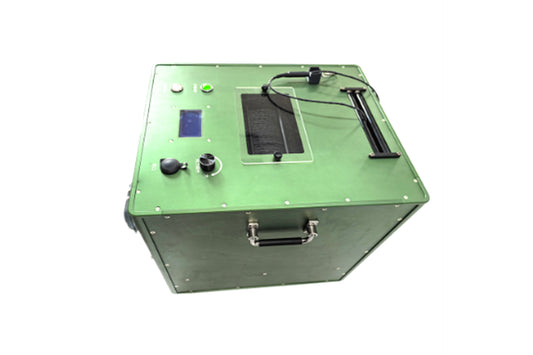

1.3 Product Photo

1.4 Main Product Specifications

| Input Voltage Range | Rated Output Voltage | Rated Output Power | Efficiency | Voltage Regulation Accuracy | Output Ripple and Noise |

|---|---|---|---|---|---|

| 800~1000Vdc | 60±0.5Vdc | 24KW | ≥97% | ≤±1% | ≤±2%Vo |

4 2. Environmental Conditions

| Item | Description |

|---|---|

| 1. Operating Temperature | Long-term operation at 24KW (Note: Specific temperature range is missing in the original document; supplement according to actual product parameters if needed) |

| 2. Storage Temperature | / (Note: Specific temperature range is missing in the original document; supplement according to actual product parameters if needed) |

| 3. Relative Humidity | No condensation (40℃±2℃) (Note: Specific humidity value is missing in the original document; supplement according to actual product parameters if needed) |

| 4. Altitude | / (Note: Specific altitude range is missing in the original document; supplement according to actual product parameters if needed) |

| 5. Atmospheric Pressure | / (Note: Specific pressure range is missing in the original document; supplement according to actual product parameters if needed) |

| 6. Heat Dissipation Method | / (Note: Specific heat dissipation method is missing in the original document; supplement according to actual product parameters if needed) |

5 3. Electrical Characteristics

3.1 Input Characteristics

| Serial Number | Item | Technical Requirement | Unit | Remarks |

|---|---|---|---|---|

| 1.1 | Rated Input Voltage | 950 | Vdc | |

| 1.2 | Input Voltage Range | 850~1000 | Vdc | |

| 1.3 | Maximum Input Current | 32 | A | Vin=800Vdc, Po=24KW |

3.2 Output Characteristics

| Serial Number | Item | Technical Requirement | Unit | Remarks |

|---|---|---|---|---|

| 2.1 | Rated Output Voltage | 60 | Vdc | / |

| 2.2 | Output Voltage Range | 56~60.5 | Vdc | |

| 2.3 | Rated Output Current | 400 | A | / |

| 2.4 | Rated Output Power | 24000 | W | / |

| 2.5 | Peak Output Power | 26000 | W | |

| 2.6 | Output Efficiency | ≥97 | % | Vin=950Vdc, load >50% |

| 2.7 | Voltage Regulation Accuracy | ±1 | % | / |

| 2.8 | Line Regulation | ±1 | % | / |

| 2.9 | Load Regulation | ±1 | % | / |

| 2.10 | Output Ripple and Noise | ≤1000 | mVp-p | Bandwidth limited to 20MHz; 10uF electrolytic capacitor and 0.1uF film capacitor connected in parallel at the test terminal; rated load |

| 2.11 | Temperature Coefficient | ±0.02 | %/℃ | / |

| 2.12 | Output Rise Time | ≤1 | S | / |

| 2.13 | Power-on Output Delay | ≤5 | S | Rated input |

| 2.14 | Power-on/Power-off Overshoot Amplitude | △V: ≤±5 | % | / |

| 2.15 | Dynamic Response Overshoot | △V: ≤±5 | % | / |

| 2.16 | Dynamic Response Recovery Time | ≤2 | ms | 75%~50% load change at 25℃; 25%~50%~25% or 50%~ (remaining load change range to be supplemented) |

3.3 Protection Characteristics

| Serial Number | Item | Technical Requirement | Unit | Remarks |

|---|---|---|---|---|

| 3.1 | Input Under-voltage Protection | 730~770 | Vdc | Hysteresis greater than 10V |

| 3.2 | Input Under-voltage Recovery | ≤800 | Vdc | |

| 3.3 | Input Over-voltage Protection | 1030~1070 | Vdc | Hysteresis greater than 15V |

| 3.4 | Input Over-voltage Recovery | ≥1000 | Vdc | |

| 3.5 | Output Over-voltage Protection | 62~66 | Vdc | Self-recoverable |

| 3.7 | Output Over-current Protection | 440~470 | A | Self-recoverable |

| 3.8 | Output Short-circuit Protection | No damage under long-term short-circuit | Self-recoverable | |

| 3.9 | Over-temperature Protection | Protection output when detected enclosure temperature >70℃, recovery at 60℃ | ℃ | Enclosure temperature |

6 4. Safety Characteristics

| Serial Number | Item | Test Condition | Remarks | |

|---|---|---|---|---|

| 1 | Dielectric Strength | Input to Output | 3000Vdc/10mA/1min | No arcing, no breakdown |

| Input to Enclosure | 2000Vdc/10mA/1min | |||

| Output to Enclosure | 1000Vdc/10mA/1min | |||

| 2 | Insulation Resistance | Input to Output | ≥10MΩ@500Vdc | Under normal atmospheric pressure, relative humidity of 90%, and test DC voltage of 500V |

| Input to Enclosure | ≥10MΩ@500Vdc | |||

| Output to Enclosure | ≥10MΩ@500Vdc |

7 5. Other Characteristics

5.1 Flame Retardant Requirement

- The flame retardant grade of the PCB used in the system shall meet the V-0 requirement specified in GB4943.1-2011.

- The flame retardant grade of the insulated cables shall meet the requirement specified in GB/T 18380.12-2008.

- The flame retardant grade of other insulating materials shall meet the V1 requirement specified in GB4943.1-2011.

5.2 System Noise

The system noise shall not exceed 60dB(A).

5.3 System Reliability

MTBF ≥100 Khour

- Test conditions: 25℃, rated input, full-load output; predicted by the stress method in MIL-HDBK-217F Notice 2.

5.4 Protection Level

The protection level shall meet the IP65 requirement. No water accumulation is allowed on the top of the power supply enclosure.

5.5 Three-proof (Moisture-proof, Mildew-proof, Salt Spray-proof)

The printed circuit boards, connectors, and other circuits in the product shall be treated with moisture-proof, mildew-proof, and salt spray-proof measures. Among them, the salt spray resistance shall meet the requirements in Table 9 of GB/T 4797.6, ensuring that the product can operate normally in outdoor humid and salt spray environments.

8 6. Product Label

Self-made or printed according to customer requirements.

9 7. Mechanical Dimensions and Connector Definition

9.2 Connector Definition (Power Part Definition)

| Function Name | Definition | Remarks |

|---|---|---|

| DC Input | VIN+ | High-voltage input positive pole |

| VIN- | High-voltage input negative pole | |

| DC Output | OUT+ | 60V output positive pole |

| OUT- | 60V output negative pole |

9.3 Weight (Net Weight)

\(\leq 9.5 kg\)

10 8. Packaging, Transportation, Storage

8.1 Packaging

- The packing box shall be marked with the product name, model, manufacturer's logo, inspection certificate of the manufacturer's quality department, manufacturing date, etc.

- An accessory list shall be included in the packing box.

8.2 Transportation

- The product shall be packed in a sturdy packing box during transportation.

- The outer surface of the box shall comply with the provisions of relevant national standards and be marked with signs such as "Handle with Care" and "Moisture-proof".

- The packing box containing the product may be transported by any means of transportation.

- During transportation, direct exposure to rain and snow and mechanical impact shall be avoided.

8.3 Storage

- Unused products shall be stored in the packing box.

- The warehouse environment shall have a temperature of -10~40℃ and a relative humidity not exceeding 80%.

- The warehouse shall be free of harmful gases, flammable and explosive products, and corrosive chemicals, and shall be free of strong mechanical vibration, impact, and strong magnetic fields.

- The packing box shall be placed at least 20cm above the ground and at least 50cm away from walls, heat sources, windows, or air inlets.

- The storage period under the specified conditions is generally 2 years. After 2 years, the product shall be re-inspected before use.

11 9. Safety Precautions

- Once the safety protection of the equipment is damaged, the equipment must be stopped and handled in accordance with the relevant maintenance regulations.

- When the power supply equipment is moved from a cold environment to a warm environment, condensation may cause electric leakage hazards. Therefore, the grounding requirement must be strictly implemented; only qualified personnel are allowed to connect the equipment to the power supply.

- After the power supply is cut off, the equipment must be shut down for 5 minutes to allow sufficient time for the capacitors to discharge before maintenance work is performed on the power supply equipment.

- Pay attention to safety in use: Avoid touching parts marked with safety warning signs or high-voltage signs to prevent electric shock or burns.

12 10. Referenced Standards and Specifications

- GB/T 2423.1-2001 Environmental Testing for Electric and Electronic Products - Part 2: Test Methods - Test A: Low Temperature

- GB/T 2423.2-2001 Environmental Testing for Electric and Electronic Products - Part 2: Test Methods - Test B: High Temperature

- GB/T 2423.3-1993 Basic Environmental Testing Procedures for Electric and Electronic Products - Test Ca: Steady-state Damp Heat Test Method

- GB/T 2423.4-1993 Basic Environmental Testing Procedures for Electric and Electronic Products - Test Db: Cyclic Damp Heat Test Method

- GB/T 2423.5-1995 Environmental Testing for Electric and Electronic Products - Part 2: Test Methods - Test Ea and Guide: Shock

- GB/T 2423.6-1995 Environmental Testing for Electric and Electronic Products - Part 2: Test Methods - Test Ea and Guide: Bump

- GB/T 2423.8-1995 Environmental Testing for Electric and Electronic Products - Part 2: Test Methods - Test Ed: Free Fall

- GB/T 2423.10-1995 Environmental Testing for Electric and Electronic Products - Part 2: Test Methods - Test Fc and Guide: Vibration (Sinusoidal)

- GB/T 2423.11-1997 Environmental Testing for Electric and Electronic Products - Part 2: Test Methods - Test Fd: Broadband Random Vibration - General Requirements

- GB/T 2423.22-2002 Environmental Testing for Electric and Electronic Products - Part 2: Test Methods - Test N: Temperature Change

- GB/T 14508-93 Mechanical Environmental Conditions for Road Freight Transportation

- EN55022:1998 Information Technology Equipment - Radio Disturbance Characteristics - Limits and Measurement Methods

- EN55024:1998 Information Technology Equipment - Immunity Characteristics - Limits and Measurement Methods

- CEI IEC 61000-4-2 2001 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Electrostatic Discharge Immunity Test

- CEI IEC 61000-4-3 2002 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Radiated, Radio-frequency, Electromagnetic Field Immunity Test

- CEI IEC 61000-4-4 1998 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Electrical Fast Transient/Burst Immunity Test

- CEI IEC 61000-4-5 1999 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Surge (Impact) Immunity Test

- CEI IEC 61000-4-6 2001 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Immunity to Conducted Disturbances, Induced by Radio-frequency Fields

- CEI IEC 61000-4-8 1993 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Power Frequency Magnetic Field Immunity Test

- CEI IEC 61000-4-11 1994 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Voltage Dips, Short Interruptions and Voltage Variations Immunity Tests

- CEI IEC 61000-4-29 2000 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Voltage Dips, Short Interruptions and Voltage Variations Immunity Tests for DC Input Ports

- IEC 61000-3-2 2001 Electromagnetic Compatibility (EMC) - Limits - Limits for Harmonic Current Emissions (Equipment Input Current ≤16A per Phase)

- IEC 61000-3-3 1994 Electromagnetic Compatibility (EMC) - Limits - Limitation of Voltage Fluctuations and Flicker in Low-voltage Supply Systems (Equipment Rated Current ≤16A)

- GB4943-2001 Safety of Information Technology Equipment

- YD/T 282-2000 General Test Method for Reliability of Telecommunication Equipment

- GB/T 13722-92 Technical Requirements and Test Methods for Mobile Communication Power Supplies

- YD/T 732-95 Test Method for DC-DC Converters for Telecommunication

- YD/T 731-2002 High-frequency Switching Rectifiers for Telecommunication

- GB14287.1-2005 Electrical Fire Monitoring Systems - Part 1: Electrical Fire Monitoring Devices