1. Overview

1. Application

This high-voltage DC power supply is a custom-made special power supply, featuring small size, light weight, high efficiency, and built-in fan for heat dissipation. The maximum operating efficiency is ≥97%. The power module adopts an aluminum shell design, which is lightweight and aesthetic, with a waterproof design. It can be used as a substitute for imported high-voltage DC module power supplies.

2. Product Features

- DC-DC Isolated Power Converter: Converts the input 750V DC power into 50V DC power in an isolated manner, with a total output power of 3000W.

- High power density, small size, and light weight.

- Design meets power supply reliability requirements: Input has over/undervoltage protection; output has overvoltage protection, current limiting, short-circuit, and overtemperature protection functions.

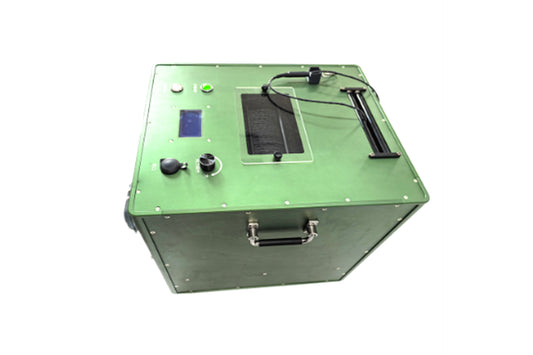

3. Product Photos

4. Main Product Specifications

| Input Voltage Range | Rated Output Voltage | Rated Output Power | Efficiency | Voltage Regulation Accuracy | Output Ripple and Noise |

|---|---|---|---|---|---|

| 700~750Vdc | 50±0.5Vdc | 3000W | ≥96% | ≤±1% | ≤±2%Vo |

4

2. Environmental Conditions

| Serial Number | Item | Technical Index | Unit | Remarks |

|---|---|---|---|---|

| 1 | Operating Temperature | -40℃~+50℃ | ℃ | |

| 2 | Storage Temperature | -40℃~+80℃ | ℃ | / |

| 3 | Relative Humidity | ≤95 | % | No Condensation (40℃±2℃) |

| 4 | Altitude | 0-2000 | m | |

| 5 | Atmospheric Pressure | 76~106 | Kpa | / |

| 6 | Heat Dissipation Method | Built-in Air Cooling | / | / |

3. Electrical Characteristics

| Serial Number 1 | Input Characteristics | |||

|---|---|---|---|---|

| Item | Technical Requirement | Unit | Remarks | |

| 1.1 | Rated Input Voltage | 725 | Vdc | |

| 1.2 | Input Voltage Range | 700~750 | Vdc | |

| 1.3 | Maximum Input Current | 5 | A | In=700Vdc, Po=3000W |

| 2 | Output Characteristics | |||

| Serial Number | Item | Technical Requirement | Unit | Remarks |

| 2.1 | Rated Output Voltage | 50 | Vdc | / |

| 2.2 | Output Voltage Range | 49.7~50.3 | Vdc | |

| 2.3 | Rated Output Current | 60 | A | / |

| 2.4 | Rated Output Power | 3000 | W | / |

| 2.5 | Output Efficiency | ≥96 | % | In=750Vdc, Full Load |

| 2.6 | Voltage Regulation Accuracy | ±1 | % | / |

| 2.7 | Source Regulation | ±1 | % | / |

| 2.8 | Load Regulation | ±1 | % | / |

| 2.9 | Output Ripple and Noise | ±2 | %/Vo | Bandwidth limited to 20MHz; 10uF electrolytic capacitor and 0.1uF film capacitor connected in parallel at the test terminal; Rated load |

| 2.10 | Temperature Coefficient | ±0.02 | %/℃ | / |

| 2.11 | Output Rise Time | ≤100 | ms | / |

| 2.12 | Power-on Output Delay | ≤5 | S | Rated Input |

| 2.13 | Power-on/Power-off Overshoot Amplitude | △V: ≤±5 | % | / |

| 2.14 | Transient Response Overshoot | △V: ≤±5 | % | / |

5

| 2.15 | Transient Response Recovery Time | ≤2 | ms | 75%~50% load change, 25℃; 25%~50%~25% or 50%~ |

|---|---|---|---|---|

| 3 | Protection Characteristics | |||

| Serial Number | Item | Technical Requirement | Unit | Remarks |

| 3.1 | Input Undervoltage Protection | 630~670 | Vdc | Hysteresis greater than 10V |

| 3.2 | Input Undervoltage Recovery | ≤700 | Vdc | |

| 3.3 | Input Overvoltage Protection | 760~800 | Vdc | Hysteresis greater than 10V |

| 3.4 | Input Overvoltage Recovery | ≥750 | Vdc | |

| 3.5 | Input Reverse Connection Protection | No Damage Under Reverse Connection | Input 750Vdc reversed | |

| 3.6 | Output Overvoltage Protection | 54~59 | Vdc | Self-recoverable |

| 3.7 | Output Overcurrent Protection | 65~72 | A | Self-recoverable |

| 3.8 | Output Short-Circuit Protection | Sustained Short-Circuit Tolerance | Self-recoverable | |

| 3.9 | Overtemperature Protection | 65 | ℃ | Internal Thermistor Temperature |

| 3.10 | Overtemperature Recovery | 60 | ℃ | |

| 4 | Parallel Current Sharing | |||

| Serial Number | Item | Technical Requirement | Unit | Remarks |

| 4.1 | Current Sharing Bus Voltage | Uniformly adjusted to 5Vdc±0.03Vdc at factory (At: 60A) | ||

| 4.2 | Current Sharing Imbalance | ≤5 | % | Output greater than 50% LOAD |

| 4.3 | Parallel Connection Method | Current sharing bus signals connected in parallel; load outputs connected in parallel | ||

| 4.4 | Number of Parallel Units | ≤6 | PCS |

4. Safety Characteristics

| Serial Number | Item | Test Condition | Remarks | |

|---|---|---|---|---|

| 1 | Dielectric Strength | Input to Output | 2500Vdc/2mA/1min | No Flashover, No Breakdown |

| Input to Enclosure | 2000Vdc/2mA/1min | |||

| Output to Enclosure | 500Vdc/2mA/1min | |||

| 2 | Insulation Resistance | Input to Output | ≥10MΩ@500Vdc | Under normal atmospheric pressure, relative humidity 90%, test DC voltage 500V |

| Input to Enclosure | ≥10MΩ@500Vdc | |||

| Output to Enclosure | ≥10MΩ@500Vdc |

5. Other Characteristics

1. Flame Retardant Requirements:

The flame retardant grade of the PCB used in the system shall meet the V-0 requirement specified in GB4943.1-2011. The flame retardant grade of insulated cables shall meet the requirements specified in GB/T 18380.12-2008. The flame retardant grade of other insulating materials shall meet the V1 requirement specified in GB4943.1-2011.

2. System Noise

The system noise shall not exceed 45dB(A).

3. System Reliability

MTBF ≥ 100Khour;Test Conditions: 25℃, rated input, full-load output; estimated by MIL-HDBK-217F Notice2 stress method;

4. Protection Level

The protection level shall meet the IP54 requirement. No water accumulation is allowed on the top of the power supply enclosure.

5. Three Protections (Moisture Proof, Mildew Proof, Salt Spray Proof)

Circuits such as printed circuit boards and connectors inside the product shall be treated with moisture proof, mildew proof, and salt spray proof. Among them, the salt spray resistance shall meet the requirements in Table 9 of GB/T 4797.6, enabling the product to operate normally in outdoor humid and sweat-salt spray environments.

6. Product Label

8. Packaging, Transportation, Storage

1. Packaging

The packing box shall be marked with product name, model, manufacturer's logo, inspection certificate from the manufacturer's quality department, manufacturing date, etc.; an accessory list shall be included in the packing box.

2. Transportation

The product shall be packed in a sturdy packing box during transportation. The exterior of the box shall comply with the provisions of relevant national standards and be marked with "Handle with Care", "Moisture Proof", etc. The packing boxes containing the products can be transported by any means of transportation. Direct exposure to rain and snow and mechanical impact shall be avoided during transportation.

3. Storage

Unused products shall be stored in packing boxes. The warehouse environment shall have a temperature of -10~40℃ and a relative humidity not exceeding 80%. No harmful gases, flammable and explosive products, or corrosive chemicals are allowed in the warehouse. There shall be no strong mechanical vibration, impact, or strong magnetic field. The packing boxes shall be padded to be at least 20cm above the ground and at least 50cm away from walls, heat sources, windows, or air inlets. The storage period under the specified conditions is generally 2 years. After 2 years, the product shall be re-inspected.

9. Safety Precautions

- Once the safety protection of the equipment is damaged, the equipment must stop working and be handled in accordance with relevant maintenance regulations.

- When the power supply equipment is moved from a cold environment to a warm environment, condensation may cause electric leakage hazards, so grounding requirements must be strictly implemented; only qualified personnel are allowed to connect the equipment to the power supply.

- After cutting off the power supply, the equipment must be shut down for five minutes to allow sufficient time for the capacitors to discharge before maintenance work can be carried out on the power supply equipment.

- Pay attention to safety during use: Avoid touching areas marked with safety warnings or high-voltage signs to prevent electric shock or scalding.

10. Referenced Standards and Specifications

GB/T 2423.1-2001 Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods / Test A: Low TemperatureGB/T 2423.2-2001 Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods / Test B: High TemperatureGB/T 2423.3-1993 Basic Environmental Testing Procedures for Electrical and Electronic Products - Test Ca: Steady Damp Heat Test MethodGB/T 2423.4-1993 Basic Environmental Testing Procedures for Electrical and Electronic Products - Test Db: Alternating Damp Heat Test MethodGB/T 2423.5-1995 Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods / Test Ea and Guide: ImpactGB/T 2423.6-1995 Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods / Test Ea and Guide: BumpGB/T 2423.8-1995 Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods / Test Ed: Free FallGB/T 2423.10-1995 Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods / Test Fc and Guide: Vibration (Sinusoidal)GB/T 2423.11-1997 Environmental Testing for Electrical and Electronic Products - Part 2: Test Methods / Test Fd: Broadband Random Vibration - General Requirements9GB/T 2423.22-2002 Environmental Testing for Electrical and Electronic Products - Part 2: Test N: Temperature ChangeGB/T 14508-93 Mechanical Environmental Conditions for Grade Highway Freight TransportationEN55022:1998 Information Technology Equipment - Radio Disturbance Characteristics - Limits and Measurement MethodsEN55024:1998 Information Technology Equipment - Immunity Characteristics - Limits and Measurement MethodsCEI IEC 61000-4-2 2001 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Electrostatic Discharge Immunity TestCEI IEC 61000-4-3 2002 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Radiated, Radio-Frequency, Electromagnetic Field Immunity TestCEI IEC 61000-4-4 1998 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Electrical Fast Transient/Burst Immunity TestCEI IEC 61000-4-5 1999 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Surge (Impact) Immunity TestCEI IEC 61000-4-6 2001 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Immunity to Conducted Disturbances, Induced by Radio-Frequency FieldsCEI IEC 61000-4-8 1993 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Power Frequency Magnetic Field Immunity TestCEI IEC 61000-4-11 1994 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Voltage Dips, Short Interruptions and Voltage Variations Immunity TestsCEI IEC 61000-4-29 2000 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Voltage Dips, Short Interruptions and Voltage Variations Immunity Tests for DC Input PortsIEC 61000-3-2 2001 Electromagnetic Compatibility (EMC) - Limits - Limits for Harmonic Current Emissions (Equipment Input Current ≤16A per Phase)IEC 61000-3-3 1994 Electromagnetic Compatibility (EMC) - Limits - Voltage Fluctuations and Flicker in Low-Voltage Supply Systems (Equipment Rated Current ≤16A)GB4943-2001 Safety of Information Technology EquipmentYD/T 282-2000 General Test Methods for Reliability of Telecommunication EquipmentGB/T 13722-92 Technical Requirements and Test Methods for Mobile Communication Power SuppliesYD/T 732-95 Test Methods for DC-DC Converters for TelecommunicationYD/T 731-2002 High-Frequency Switching Rectifiers for TelecommunicationGB14287.1-2005 Electrical Fire Monitoring Systems - Part 1: Electrical Fire Monitoring Devices