The AF-G4-100M UAV tethering case can be combined with an onboard module to form a tethering system compatible with multiple UAV platforms. The system primarily comprises a retractable winch, a tethering case, integrated tethering cables, and an integrated tethered ground power supply. This system provides wired power, information transmission, and cable retraction for the tethered drone. The retractable winch includes a system case, a main frame, a cable storage reel, and control circuitry.

| Items | Technical Parameters |

| System Box Dimensions | 375mm*345mm*225mm (L/W/H) |

| System Box with Handle | 420mm*345m*225mm (L/W/H) |

| Control Panel Dimensions | 100m |

| Cable Length | 13.5kg±0.5kg |

| Weight | 220Vac |

| External Power Supply | ≤2m/s |

| Maximum Rewind Speed | Passive Payout/Active Reel-In |

| Operating Mode | 400Vdc (30Vdc Compensation) |

This tethered system solves the four major limitations of multi-rotor drones: 1. Flight time: After connecting to the tethered platform, multi-rotor drones can complete fixed-point flight missions that require long-term continuous operation in specific scenarios without being restricted by battery capacity. 2. Safety: In special areas such as no-fly zones, crowded areas, and flammable and explosive areas, tethered drones can minimize risks while performing missions to the greatest extent possible. 3. Ease of use: Tethered drones can be easily operated with simple flight skills. 4. Support for high-power mounting: The airborne end has a high-power power output interface, and the drone can hang higher-power loads. Features: (1) All-aluminum alloy shell, small size, light weight, less than 14kg. (2) Simple operation, one-button start of high-voltage output, one-button automatic retraction. (3) No need to modify the aircraft, just install the airborne end module and it can be used. (4) The shell color and text language support batch customization. (5) Customizable fiber optic communication. (6) Two modes of transportation are available: backpack or trailer.

3. Instructions for use

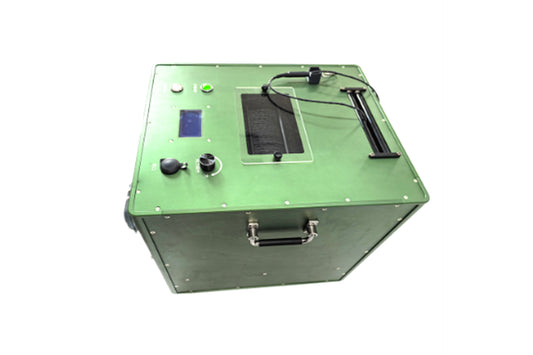

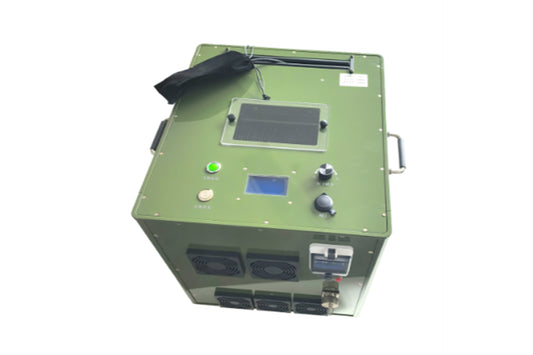

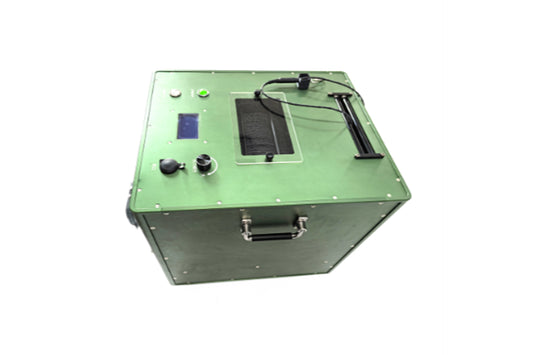

1. Description of the mooring box panel:

(1) Main power circuit breaker: the main switch for all electrical devices, including the mooring box control power supply and the mooring power main power;

(2) Main power switch button: the switch button for the aircraft power supply. When pressed, the system high-voltage DC is energized and outputs 400V DC high voltage to supply power to the drone onboard power supply;

(3) Main power switch indicator (integrated on the main power switch button ring light): used to indicate the mooring box power supply status;

(4) Torque adjustment knob: used to control the torque of the reeling;

(5) Transparent panel: used to visually observe the winch cable length status.

(6) LCD display information:

Output voltage: displays the current ground power output DC voltage value

Output current: displays the current ground power output DC current value

Output power: displays the current ground power output power value

Input voltage: displays the current ground power input DC voltage value

2. Wiring Instructions

(1) Connect the power cord provided with the assembly from the mains or generator to the mooring box. Plug one end directly into the mooring box socket, and the other end can be directly connected to the mains or generator.

(2) The high-voltage cable output of the mooring box is an XT90 connector. Connect the cable to the drone's onboard power supply as shown below, and secure the load-bearing hook (the load-bearing hook pulls the wire to bear the force).

3. Operating Instructions

(1) During operation, first adjust the torque adjustment knob to the lowest position, then close the circuit breaker to power on the system. At this time, the display on the panel lights up.

(2) When the drone is ready to take off, adjust the torque knob to the lowest setting or slightly increase the torque (in windy conditions), and pull the cable out through the drone. When reeling in the cable, adjust the torque knob from small to large to synchronize with the drone's descent speed. You can also adjust the torque to the appropriate torque from the start to always keep the cable at a certain tension. The drone will release the cable and force the cable to hover. When landing, the cable will automatically reel in due to a certain tension. (3) When the drone needs to be powered, press the "main power switch" button. The tethered box cooling fan will start working, and the "main power operation" indicator light will be on. The display will show the current output voltage, current output current and output power of the cable main power. When the system is loaded with current, the indicator light will turn on and the aircraft will be powered. It is recommended to turn on the main power when the aircraft takes off 5m or the blades start to rotate. When the aircraft descends to 5m above the ground, turn off the main power to prevent the inevitable reverse electromotive force shock to the onboard module. (4) After the task is completed, turn off the main power switch first, and the high-voltage DC power supply is disconnected. When performing the remaining cable reeling operation, prevent accidental electric shock. Finally, turn off the main power switch and unplug the power cord. Notes 1) Before starting to use, please try to level the equipment and keep it in a relatively balanced state; 2) Operators must wear insulating gloves to prevent accidental electric shock; 3) When adjusting the speed knob, turn it slowly from small to large, and do not adjust it to the maximum suddenly; 4) After reeling, wrap the power cord and place it in the box. Do not drag it on the ground; 5) The mooring cable should not be dragged on the ground during use to avoid linting. Pay attention to whether there are stones or other sharp objects on the ground to avoid cutting the cable. IV. Product Maintenance and Warranty After-Sales 1. Storage and Transportation When transporting the mooring power supply box, it must be treated with shock absorption. Otherwise, it is normal for the internal screws to loosen. 2. Maintenance (1) Check and maintain the tethered power supply every 50 takeoffs and landings or 20 hours of flight to ensure that the tethered power supply is functioning properly. (2) Check whether the various components of the tethered power supply have been subjected to strong impacts and whether the movable parts of the tethered power supply are still running smoothly. Inspection: 1) Cable inspection: Carefully check the entire length of the tethered cable for damaged outer sheath, exposed armor, excessive bends, or bent/contaminated connector pins. This is the most important step. 2) Interface cleaning: Disconnect all electrical connectors, check and clean the dust and moisture in the interface, and ensure that it is dry and clean. 3) Lamp body and module cleaning: Use a dry soft cloth to wipe the lighting body and power module housing to ensure that the ventilation holes are not blocked. 4) Standard storage: Store the cables neatly in a coiled manner, avoid small radius bends, and store in a cool and dry place.